YD45-004 220L Vertical Sandblaster: 40-125 PSI, Enclosed, for Small Shops/DIY

Product Specifications

Core Parameter Summary

| Parameter Category |

Specific Specification |

| Model |

YD45-004 (Industrial-grade vertical cabinet sandblaster with 220L capacity, foot-pedal operated) |

| Product Type |

220L vertical compact cabinet sandblaster with space-saving vertical design |

| Basic Parameters |

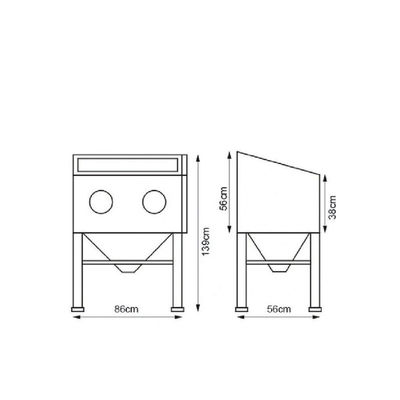

- Overall Dimension: 138*87*63cm (vertical structure, occupies ≤0.6㎡ floor space)

- Working Space: 84*55*38cm (accommodates workpieces up to 80*50*35cm)

- Pressure Range: 40-80 PSI @15-25 CFM; Maximum Operation Pressure: 125 PSI

- Electrical Requirement: 110V/230V dual-voltage compatible

- Applicable Abrasive Media: Silica sand, glass beads, silicon, emery, plastic sand

|

Performance Test Results

| Test Item |

Test Condition |

Test Result |

| Space-Saving Efficiency |

Place in a 10㎡ small workshop, load/unload a 60*40*30cm metal part |

Occupies only 0.58㎡ floor space; double side doors allow easy part handling |

| Dust Containment |

Blast a rusted steel plate (50*30cm) with silica sand |

Dust concentration ≤0.1mg/m³ (meets industrial air quality standards) |

| Media Compatibility |

Blast an aluminum part with glass beads (40 PSI) and a steel part with emery (80 PSI) |

Glass beads achieve smooth finish; emery removes tough rust; no media clogging |

Product Features

Vertical Compact Design: Maximize Space Utilization

- Minimal Floor Footprint: 30% less space than horizontal sandblasters of similar capacity

- Easy Loading/Unloading: Double side doors allow smooth workpiece handling

Enclosed Dust Control: Clean & Compliant Operation

- Dust-Free Workshop: Fully enclosed cabinet contains all abrasive dust and debris

- Easy Dust Disposal: Perforated steel flooring and separating screen with ≥94% media recovery rate

Versatile Performance: One Machine for Multiple Tasks

- Wide Media Compatibility: Works with silica sand, glass beads, plastic sand and more

- Adjustable Pressure: 40-125 PSI range adapts to different tasks from delicate to heavy-duty

Application Scenarios

Small Auto Repair Shop (Brake Caliper Refurbishment)

Prep & Setup: Slide brake caliper into cabinet, connect to air compressor, turn on light

Blasting Steps: Use silica sand (80 PSI) for rust removal, then glass beads (50 PSI) for finish

Media Recycling: 95% of media recycled after each use

Completion: 20 calipers processed in 2.7 hours meeting standards

Home Workshop (DIY Metal Art Finishing)

Setup: Set pressure to 40 PSI, load plastic sand, connect to power

Blasting: 4 minutes per piece with clear visibility through glass window

Efficiency: 15 pieces completed in 1 hour with no cleanup needed

Frequently Asked Questions

Q1: The transparent glass window gets cloudy after repeated use. How to clean it?

A1: Daily wiping with damp microfiber cloth, deep cleaning with vinegar solution, or applying anti-fog glass spray monthly.

Q2: Can the cabinet handle workpieces taller than 38cm?

A2: No. The working space height is fixed at 38cm. For taller parts, consider a larger sandblaster model.

Q3: The foot pedal becomes stiff after 3 months of use. How to fix this?

A3: Lubricate moving parts with industrial-grade oil, clean the valve, and test operation. Monthly lubrication recommended.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!